KALPOXY®

Corrosion Resistant Coatings

KALPOXY® coatings are epoxy resin-bonded compounds with high resistance to wear, which can be used quickly and effectively for repair work and in the lining of plant and equipment components. These 100% solids high build epoxy coatings are based on a unique blend of liquid epoxy polymer and aliphatic polyamine curing agents, which can displace water from wet surfaces to make a permanent bond. The formulation is solvent-free to ensure safety and maximum technical performance. Kevlar®* fibers are incorporated for reinforcement and viscosity management to achieve high application rates, even underwater.

KALPOXY® Coatings

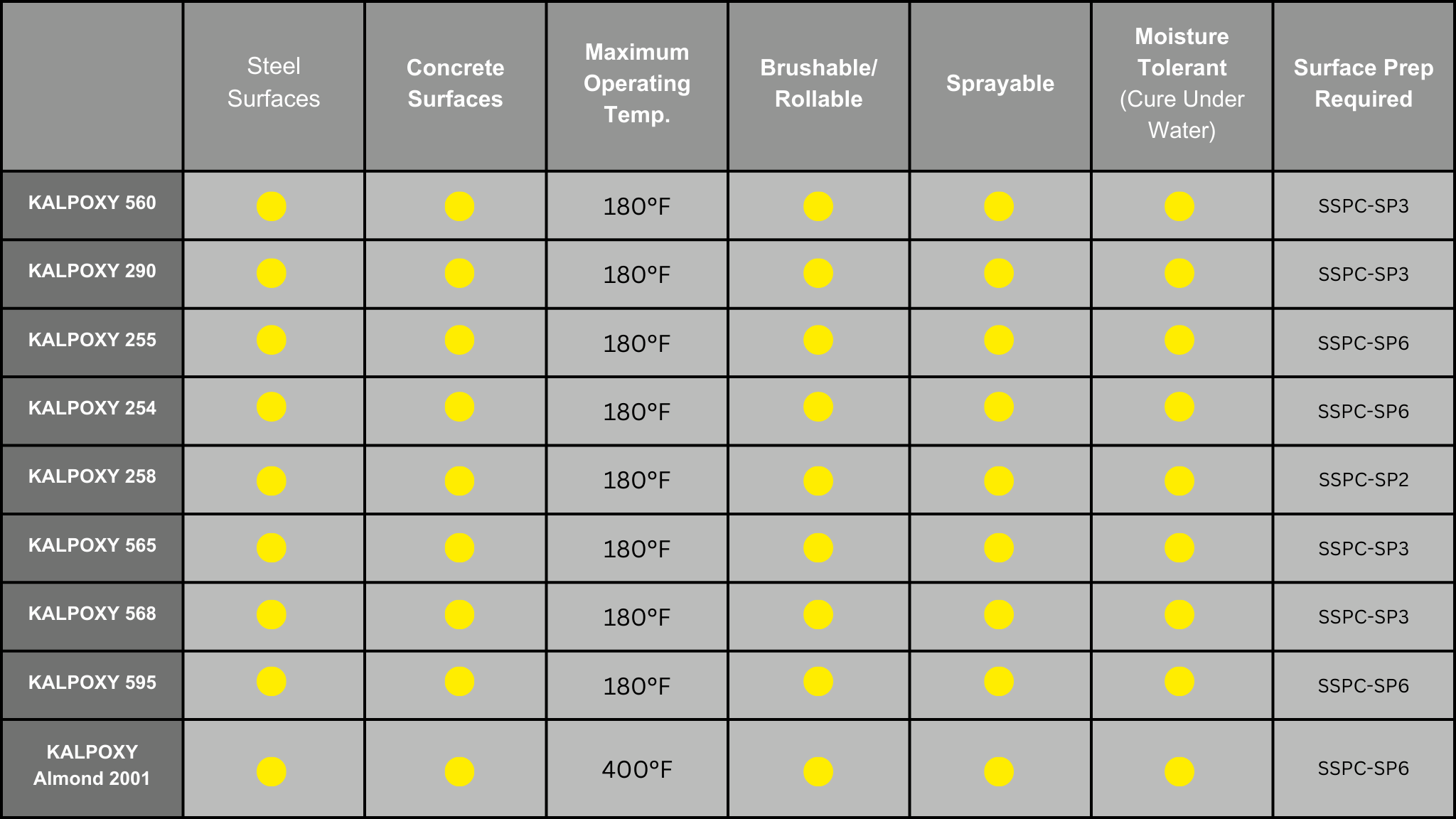

- KALPOXY® 255 – Formulation designed for tough Corrosive/Erosive Conditions. Available in formulations for spray or Roller/Trowel applications.

- KALPOXY® 258 – Based on a unique blend of liquid epoxy polymer and aliphatic polyamine curing agents, which can displace water from wet surfaces to make a permanent bond.

- KALPOXY® 560 – Solvent free formulation which can displace water to make a permanent bond to all substrates with minimal substrate preparation.

- KALPOXY® 290 – Same as our 560 products but designed for application with roller, brush or conventional spray equipment. Complete with UV protective additive to eliminate chalking.

- KALPOXY® 565 – Same as our 258 products but the formulation is uniquely field-friendly, non-hazmat and supplied in the most preferred 1/1 by volume mixing ratio.

- KALPOXY® 568 – For structural steel and galvanized surfaces in atmospheric service.

- KALPOXY® 595 – Formulation promotes sliding with no contamination. Suitable for covering concrete and steel surfaces and uniquely designed to be abrasion and impact resistant.

- KALPOXY® 254 – Ensures safety and maximum technical performance under the most adverse conditions including exposure to most industrial chemicals such as acids, alkalis and hydrocarbons.

- KALPOXY® Almond 2001 – “Nuclear quality” coating, self-priming and approved for some Service Level 1 nuclear applications.

KALFIX® Adhesives

- KALFIX® 911 – “5-Minute” epoxy filler with extreme adhesion even to underwater surfaces. Used primarily as a pressure-transfer filler under high pressure pipeline repair composites.

- KALFIX® 913 – Longer pot life version of 911. “15-Minute” epoxy filler with extreme adhesion even to underwater surfaces. The formula is uniquely field-friendly using advanced low toxicity ingredients and can be shipped “Non-Regulated” by USDOT, IATA and IMO.

- KALFIX® 563 – “45-Minute” curing version of KALPOXY 560 for pipeline coating or cold weather use.

- KALFIX® 206 – Combination liquid epoxy resin and a special high temperature curing agent. Although this epoxy has a high heat distortion, is still cures to a hard and dust-free condition at normal temperatures.

KALPOXY®Coatings Guide