KALMETALL

Hard overlay welding KALMETALL

Hard overlay welding for very high impact and abrasion resistance. Cost-Effective Protection for Abrasive Applications.

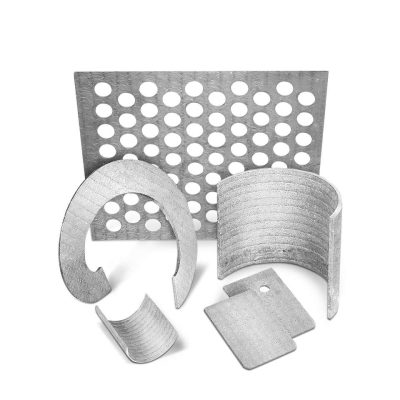

KALMETALL is a metallic material that is produced by applying hard build-up welding to sheet steel.

As a manufacturer, we can specifically control the properties of the hard overlay welding by changing the welding filler materials and adjusting them precisely to the needs of the application.

The plates manufactured by Kalenborn are characterized by excellent abrasion and impact resistance. As a rubber composite KALIMPACT, a high reduction of noise and vibration is possible. These properties open up a wide range of applications for KALMETALL in numerous industrial plants.

Typical applications are screw conveyors, fan housings, cyclones and classifiers, mixer liners, piping components, screens, troughs, and conveyor troughs.